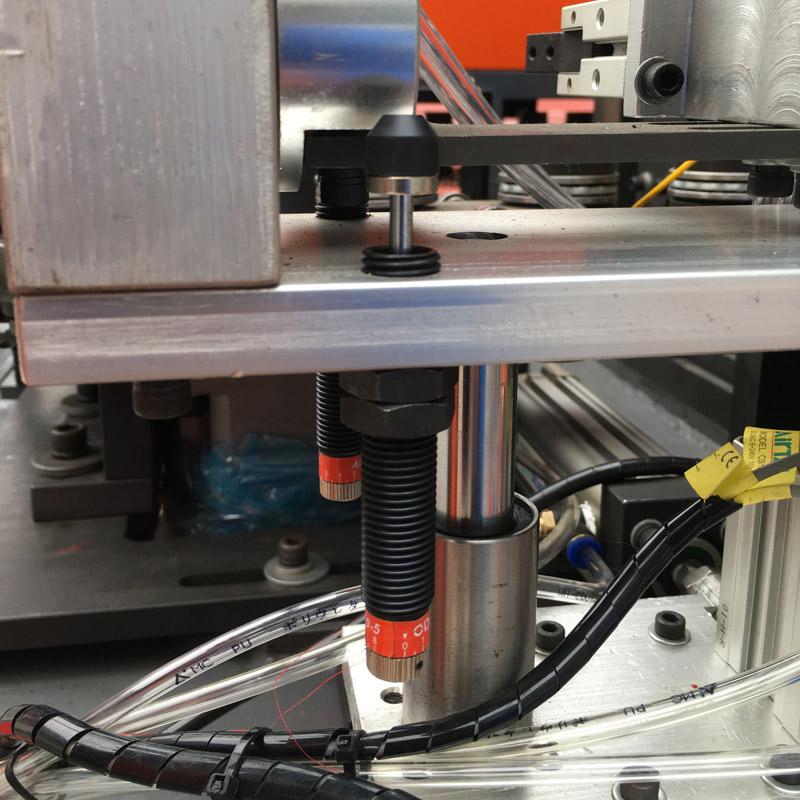

TH-A1 Automatic bottle blowing machine for cosmetic bottles

Automatic Bottle Blowing Machine for Plastic Jar , Hand feeding PET Wide Mouth Blow Molding Machine Manufacturer 1. Machine application field Single cavity or two cavities, can blow all kinds of shapes, different volumes of candy-jars, other shapes of containers using PET as... 1. Machine application field Single cavity or two cavities, can blow all kinds of shapes, different volumes of candy-jars, other shapes of containers using PET as material. 2. Features of machinery for blowing PET jar 1.Using hydro-pneumatic linkage mold clamping mechanism which runs stably with high speed and great clamping force. 2.The control system adopts man-machine interface with Mitsubishi PLC which is of high sensitivity and accuracy. 3.Using coated infrared heating lamps which enable fast and stable heating. 4.Using centralized noise-reducing air recycling system which minimize the noise as much as possible. 5.Using slide core in stepping unit which is easy to operate and saves energy. 6. Cooperation with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine; 7. Guarantee & Service a. Reply the email and take action in 24 hours. b. 100% Quality inspection before the shipment. c. Can training clients operator for free in seller's factory. d. Engineer overseas is available. e. Blowing mold and injection mold made original. f. Auxiliary machines for complete line. g. Customized design as requirements.